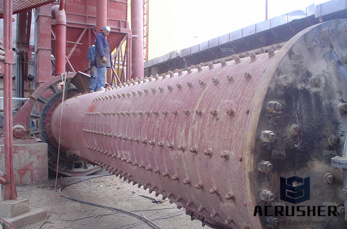

Gold Mining Machine Ball Grinder Mill for Iron Gold Lead ...

Quality Mining Ball Mill manufacturers exporter buy Gold Mining Machine Ball Grinder Mill for Iron Gold Lead Zinc Ore 320kw from China manufacturer.

WhatsApp)

WhatsApp)

Quality Mining Ball Mill manufacturers exporter buy Gold Mining Machine Ball Grinder Mill for Iron Gold Lead Zinc Ore 320kw from China manufacturer.

Gold CIL (Carbon in Leach) Process is an efficient design of extracting and recovering gold from its ore. By cyaniding and carbon leaching crushed gold ore slurry simultaneously, CIL process lower the gold mining operation cost and increase gold recovery rate to a degree of 99%.

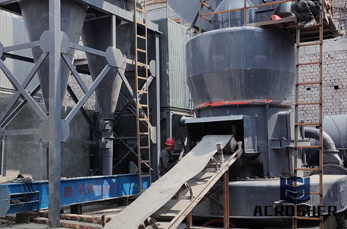

New and Used Ball Mills for Sale Savona Equipment is a new and used Ball Mill supplier ball mill is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering.

A comparison of wear rates of ball mill grinding Journal of Mining and Metallurgy, 52 A (1) (2016 ) 1 10 # Corresponding author :

In the future, Xinhai will continue to rely on three big supporting "technology, talents, management", adhere to the international development strategy, and concentrate on providing customers with modern, efficient, energysaving mine overall construction and operational solution, to create international leading enterprises in mining industry.

In all methods of gold ore refining, the ore is usually washed and filtered at the mine, then sent to the mill. At the mill, the ore is ground into smaller particles with water, then ground again in a ball mill to further pulverize the ore.

We have designed a turnkey ore processor with handsfree operation in mind. This costeffective solution requires no computers nor electronics, making it easy to run and maintain. The system scales to your growth, as well, incorporating ball mills or flotation plants to keep up with commerciallyviable mining .

GRINDING MEDIA QUALITY ASSURANCE FOR THE COMMINUTION OF GOLD ORES 27 ... GRINDING MEDIA QUALITY ASSURANCE FOR THE COMMINUTION OF GOLD ORES 29 porosity of the grinding balls must be corrected, since it ... such as gold ore are milled, especially in large ball mills.

ore ball mill media for mining rock ore ball mill media for mining rock Autogenous and Semiautogenous mills . The AG/SAG mills are utilized to grind run of mine rock or primary ... size for further grinding in a ball mill, pebble mill, or a VERTIMILL® or a stirred media...

ORE GRINDING EQUIPMENT Most of the tonnage milled today is ground in one of the following types of equipment or a combination of two or more: ball mills, tube mills, rod mills, and stamps. Chilean mills and Huntington mills are used only in a few isolated cases today. BALL AND TUBE MILLS All types of Ore Grinding Mills that consist [.]

Ball mills have been the primary piece of machinery in traditional hard rock circuits for 100+ years. They are proven workhorses, with discharge mesh sizes from ~40M to <200M. Use of a ball mill is the best choice when long term, stationary milling can be justified by an operation.

China Overflow Ball Mill for Gold Ore Mine Plant, Find details about China Ball Mill, Mineral Process Machine from Overflow Ball Mill for Gold Ore Mine Plant .

China mining mill grinding balls china steel ball ball steel ball ball grinding media manufacturer supplier in china offering mining mill grinding balls dia 65mm 75mm good wear rate 65mn grinding steel rod for coal mill dia 20mm150mm steel mill balls gri,75mm wearable grinding steel ball for gold ore and mines.

A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium. Different materials are used as media, including ceramic balls, flint pebbles and stainless steel balls.

Ore is stockpiled (1) at the processing plant, and the process begins by feeding the ore into a hopper with a loader. The ore is conveyed, and lime is added (2) to raise the pH of the ore. Following crushing through a jaw crusher (3), the ore is fed into the semi autogenous grinding (SAG) mill (4) along with water and steel balls.

Grinding in small plants, as in larger installations, has proven to be the most costly of all unit operations from both capital and operating standpoints. Therefore, grinding deserves the most scrutiny of all operations during the design procedure. A recent survey by a major grinding mill manufacturer reveals that more than 80 autogenous or semiautogenous mills having between 100 and 1,000 ...

A wide variety of gold mining ball mill options are available to you, There are 8,828 suppliers who sells gold mining ball mill on, mainly located in Asia. The top countries of suppliers are China, India, and South Korea, from which the percentage of gold mining ball mill .

Wide Application of Ball Mill Ball mill, as the key grinding equipment of the materials, is widely used for mineral grinding such as cement, lime, quartz, slag, silica, iron ore, copper ore, gold ore, bauxite, calcite, barite, gypsum and other minerals in mining, quarry, chemical, cement and other industries.. Ball mill is the necessary equipment in ore beneficiation plant.

Ball Mill For Gold – Mining Equipment for Sale,Stone Crushing . Ball mill or ball grinder, can be a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic garbage and paints.

Gold Ore Forged Steel Grinding Media Ball For Ball Mill

Mine Mining Grinding Ball Mill Gold Ore. There is no standard solution for mineral industry and wear rate of grinding media varies from mine to mine, ore to ore and even for the same ore time to timeifferent alloys are recommended depending on ore type and mill particulars in order to arrive at the most cost economic solution.

gold mining ore fine crushing grinding ball mill Mount Isa Lead, Zinc and Silver Mine Mining A 1923 silver lead ore discovery in Queensland, Australia, lead to the formation of Mount Isa Mines and the development of one of the world''s great mines.

In all ore dressing and milling Operations, including flotation, cyanidation, gravity concentration, and amalgamation, the Working Principle is to crush and grind, often with rob mill ball mills, the ore in order to liberate the minerals. In the chemical and process industries, grinding is an important step in preparing raw materials for subsequent treatment.

Sep 11, 2018· Video showing our ball mills for 1 and 2 tons per hour. These mills can crush quartz ore and liberate the gold and sulfides for concentration with our shaker tables. Check out our other videos of ...

WhatsApp)

WhatsApp)