Ball mill drive motor choices

Ball mill drive motor choices Conference Paper in Cement Industry Technical Conference, 1988. Record of Technical Papers., 30th IEEE · February 2000 with 105 Reads

WhatsApp)

WhatsApp)

Ball mill drive motor choices Conference Paper in Cement Industry Technical Conference, 1988. Record of Technical Papers., 30th IEEE · February 2000 with 105 Reads

Located at Kennecott Ut Copper near Salt Lake, this mill uses a ringmotor drive, Figure 5. The SAG mill is followed by two 20ft diam., 7,500hp geardriven ball mills.

Ball Mill Motor Drive ball mill motor drive schemes . Technical evaluation and practical experience of highpower . Grinding mill drives play an important role in the mining industry. . the static power converter and .

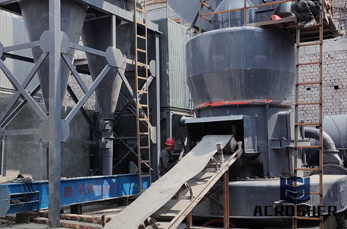

Mill drive arrangement. Mill drives are generally located on the outside of the mill to facilitate maintenance. ... Conveyor motor drive scheme. ... Ball mills are operated at higher speed so that the balls can be thrown up and strike back to the other wall with increased speed of hitting the ore particles. Ball mills are suited for finer ...

The drive configuration for this project known as SBRS (Start Ball, Run SAG) meaning that the VSD is to soft start with frozen charge detection the ball mill, run up to nominal speed, smoothly connect ball mill to the grid so that the ball mill is operating with fixed speed, then soft start with frozen charge detection the SAG mill as well as ...

The inching drive, also known as a barring or auxiliary drive, is an important component of any mill or kiln installation. It is used for maintenance and inspection purposes, as well as an emergency auxiliary drive to keep kilns rotating when the main motor fails. This .

ball mill motor drive schemes . BALL MILL DRIVE MOTOR CHOICES Raymond grinding millIt is assumed that there is an additional 1300 kW on line at the time of t Read More Biffa''''s ball mill waste site stench returns, say residents in.

10 100tph ball mill price in britain. drive motor required for tph cement ball mill . 10 100tph Ball Mill Price In Britain 10 1000tph ball mill price in uk 200 Tph Ball Mill Cost drive motor required for 100 tph cement ball mill cost of a . Get Price. lose coal mill . 100tph clinker grinding mill

Jan 19, 2016· The mills at Sentinel in Zambia are amongst the world''s biggest, with 2 off 40 ft SAG mills complete with 28 MW drives, and 2 off 28 football mills with 22 MW drives. For mines of this size ...

These large coal crushing drive systems are usually rotated by motordriven gearing. A typical application consists of a motordriven primary singlestage reducer that, through a flexible coupling, drives a large open pinion which in turn, meshes with a large ball mill ring (girth) gear that is attached directly to the ball mill.

May 12, 2000· Abstract: The time has come to rethink the approach to mill drive motors because of the growth in size of newer ball mills, the starting torque restrictions of some of the newer mill drive configurations, and the softness of some utility services. This paper looks at the serviceability and economics of five different mill motor options to meet these restraints.

BALL MILL DRIVE MOTOR CHOICES The time has come to rethink our approach to mill drive motors because of the growth in size of newer ball mills, the starting torque restrictions of some of the newer mill drive The mill used for this comparison is a diameter by meter long ball mill with a 5000 HP drive motor.

The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum ''chunk size'', product size as P80 and maximum and finally the type of circuit open/closed ...

ABB''s GMD is the most powerful mill drive system in the market to power semiautogenous (SAG), ball and autogenous (AG) mills, This ''workhorse'' for grinding operations combines a robust, servicefriendly and fit for purpose design to provide highest throughput, reliability .

Nov 22, 2013· Full loaded Ball Mill start using MV VFD controlled synchronous motor Duration: 0:31. Maxim Stepanov 3,952 views. 0:31. Off Grid Winch: ...

May 02, 2018· An inching drive is used as an auxiliary system to the main drive for a large machine such as a ball mill, industrial kiln, conveyor, or elevator. Its purpose is to turn the equipment at a speed slower than the normal operating speed — typically 1 to 2 rpm, although fractional rpms are also common — and to do so at high torque — typically ...

•The gearbox between motor ball mill had been recently rebuilt. •Two identical ball mills were in place at the plant (1A 1B). •These machines are used to pulverize or crush lime into small particles (dust) that is then made into a slurry and injected into the flue gases to reduce pollution.

Ball Mill Drive Motors. ball mill motor drive schemes acherishedbirth. · ball mill motor drive schemes_Msw Municipal Waste Sorting Line Equipment For Waste The motor drives the transmission system to rotate. . Our professional engineers will design the most reaso.

Ball mills are commonly used in the manufacture of Portland cement and finer grinding stages of mineral processing, one example being the Sepro tyre drive Grinding Mill. Industrial ball mills can be as large as m (28 ft) in diameter with a 22 MW motor, [4] drawing approximately % of the total world''s power (see List of countries by ...

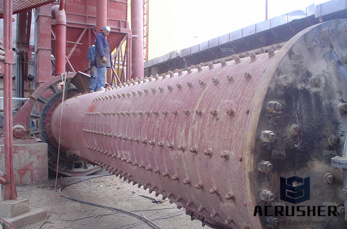

The mill used for this comparison is a 44meter diameter by 136 meter long ball mill with a 5000 HP drive motor It is designed for approximately 90 ston per hour This type twocompartment mill is a state oftheart shell supported cement finish mill The torque

Motor The GMD is a drive system without any gear where the transmission of the torque between the motor and the mill is done through the magnetic field in the air gap between the motor stator and the motor rotor. The concept to drive the mill this way is relatively simple using the mill body as motor rotor and mounting the poles there.

In twin motor drive systems, ... The subject of this paper is a synchronous drive of grinding ball mills 4 MW, 150 rpm, 6 kV, 50 Hz on the base of PWM CSI. ... The advantages of this scheme are ...

The SIMINE Gearless mill drives pump system significantly enhances concentrator productivity by eliminating the reducer gear between motor and pump and all corresponding maintenance. In addition, the cyclone pumps with variable speed can adjust their energy consumption to the optimized flow of pulp, resulting in energy savings of up to 30%.

BALL MILL DRIVE MOTOR CHOICES. dual pinion gear driven mill; a Drive 5 A 5000 HP, 1200 rpm synchronous induction motor with liquid rheostat and dc The mill used for this comparison is a diameter by meter long ball mill with a 5000 HP drive motor.

WhatsApp)

WhatsApp)