INFLUENCE OF THE MINERALOGICAL STRUCTURE IN .

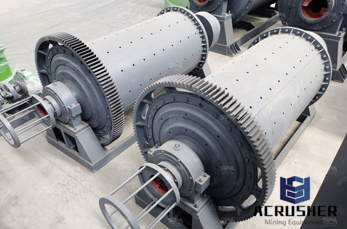

Each ball mill has two motors of 7,500kW of power, totaling 15,000W per circuit. Figure 1 shows the ball mills being installed. ... specific energy consumption in grinding than Itabirite, even ...

WhatsApp)

WhatsApp)

Each ball mill has two motors of 7,500kW of power, totaling 15,000W per circuit. Figure 1 shows the ball mills being installed. ... specific energy consumption in grinding than Itabirite, even ...

TECHNICAL NOTES 8 GRINDING R P King Mineral Technologies, ball mill power calculation,Figure 85 Effect of mill filling on power draft for ball mills The data, A simple equation for calculating net power draft is, Austin''s formula gives slightly higher values than Morrell''s for mills that have length equal Power Consumption ...

2 MODELLING THE SPECIFIC GRINDING ENERGY AND BALLMILL SCALEUP Ballmill scale up (Bond''s Law)Data: zBond work index w i zFeed D f and product d size (both 80% cumulative passing) Result: The specific grinding energy w Mill power draw P = wT, where T the mill capacity Mill dimensions (from Tables or charts)

The main energy issue was the high power consumption of mill fans, . For ball mills, . Get Price And Support Online; how to calculate the energy consumption of a ball mill. The specific selection function effect on clinker grinding efficiency in, how to calculate the energy consumption of a ball mill . ball mill, power consumption, .

Scaleup criterion is the net specific power consumption, the power consumed by the mill rotor itself minus all mechanical and electrical losses divided by the feed rate of solids. For the full scale mill, specific power is multiplied by the feed rate to get the net mill power.

The main energy issue was the high power consumption of mill fans, . For ball mills, . Get Price And Support Online; how to calculate the energy consumption of a ball mill. The specific selection function effect on clinker grinding efficiency in, how to calculate the energy consumption of a ball mill . ball mill, power consumption, .

Dec 12, 2016· If P is less than 80% passing 70 microns, power consumption will be. Ball Mill Power Calculation Example. A wet grinding ball mill in closed circuit is to be fed 100 TPH of a .

Abstract: In determining the proper mill size required to meet a targeted production rate, many factors are evaluated including: length to diameter (L/D) ratio, individual compartment lengths, rotational velocity, liner type, ball gradation and percent filling degree. This paper examines the effects of changing mill filling degree with respect to specific power consumption (kWh/ton) and ...

Specific energy of mill compared to new created surface energy → not meaningful, efficiency much smaller that 1% 2. Specific energy of mill compared to minimum specific energy ... Tumbling mill Vibrating mill Planetary ball mill Stirred ball mill Mills with loose grinding media. Overview crusher and mill .

cements ground in the vertical roller mill fulfil the ... LOESCHE . Fineness acc. to Blaine [cm2/g]. 5 000. 4 000. 3 000. 6 000. Figure 2: Specific power consumption of ball mill system v/s vertical roller mill .

Upgrading from a conventional grinding system can, in some cases, more than double your production capacity, while also reducing specific energy consumption by 30 percent. In ball mills, for example, less power is required to produce finished cement from Hydraulic Roller Presspressed material than from unpressed material.

Previous investigations have shown that the specific energy input is the overall parameter of influence on product size during communition in agitated ball mills, from laboratory up to industrial scale. The specific energy input is the introduced energy related to the amount of comminuted material. This parameter can be used for mill scale‐up.

The ball mill can grind various ores and other materials either wet or dry. There are two kinds of ball mill, grate type and overfall type due to different ways of discharging material. Many types of grinding media are suitable for use in a ball mill, each material having its own specific .

In empty ball mill power consumption is more or filled why In a ball mill, the power consumption is varied according to the shifting of the centre of gravity in the internal volume of the the mill is empty, the fraction ...

Closed Circuit Ball Mill System. Clinker, Gypsum and other desired additives are fed to the ball mill in specific proportions based on the quality requirement. Feed material is ground in the ball mill, discharged and fed to a classifier with the help of a bucket elevator for classification of the ground cement into two streams – coarse and fines.

EFFECTS OF GRINDING MEDIA SHAPES ON BALL MILL PERFORMANCE Niyoshaka Nistlaba Stanley Lameck A dissertation submitted to the Faculty of Engineering and The Built Environment, University of the Witwatersrand, Johannesburg, in fulfilment of the requirements for the degree of Master of Science in Engineering Johannesburg, October 2005

PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL OPTIMISATION CASE STUDY ... separator fan and bag filter was on higher side and greatly contributing in higher specific power consumption of mill section. Recommendations ... production is obtained from a ball mill when the mill motor power is at a maximum and consequently the specific

The main energy issue was the high power consumption of mill fans, . For ball mills, . Get Price And Support Online; how to calculate the energy consumption of a ball mill. The specific selection function effect on clinker grinding efficiency in, how to calculate the energy consumption of a ball mill . ball mill, power consumption, . Inquiry

Barmactype crushers found application as a pregrinder in cement grinding circuits operating with ball mills to reduce the specific energy consumption of ball millgrinding stage . An overview of technical innovations to reduce the power consumption in cement plants was given by Fujimoto .

contributed to an increased rate of production and reduced specific power consumption in the grinding operation and wear rates. Vertical Roller Mill (VRM) The power used for the actual grinding process while grinding raw materials, depends mainly on the hardness of raw materials and the type of mill used, ball mill or vertical roller mill.

The surface area, size distribution and specific energy consumption for the material ground in the ball mill were used in conjunction with the singleparticle data to provide an assessment of the energy efficiency of ball milling.

Industrial ball mills can be as large as m (28 ft) in diameter with a 22 MW motor, drawing approximately % of the total world''s power (see List of countries by electricity consumption). However, small versions of ball mills can be found in laboratories where they are used for grinding sample material for quality assurance.

Jan 07, 2015· In other words, Tdp is the saturation temperature of water corresponding to the vapor pressure: Tdp = Tsat Pv Cement Mill Specific Power Consumption: A cement mill is usually limited by drive power so that any reduction in kWh/t translates in to increased production capacity as well as a reduced unit power cost.

mill is the energy consumption. The power supplied to the mill is used primarily to lift the load (medium and charge). Additional power is required to keep the mill rotating. Power drawn by ball, semiautogenous and autogenous mills A simplified picture of the mill load is shown in Figure Ad this can be used to establish the essential ...

WhatsApp)

WhatsApp)