Homemade Ball Mill Tumbles Along Like A Champ | Hackaday

Mar 18, 2014· Has anyone had any experience ball milling aluminum powder to upgrade it''s quality to that of German dark? I''m interested in hearing the results of their work.

WhatsApp)

WhatsApp)

Mar 18, 2014· Has anyone had any experience ball milling aluminum powder to upgrade it''s quality to that of German dark? I''m interested in hearing the results of their work.

Oct 12, 2006· Aluminum Powder Question posted in Newbie Questions: Okay, I know Flash powder is frowned upon here, but that is NOT my question. Please no major flaming, I am still learning some am wondering what the difference is between German Blackhead / Indian Blackhead/ normal Aluminum powder (10micron) 1250 mesh / Aluminum powder (20micron) 625mesh is.

Nov 01, 2015· Stearic acid (97% purity, Fisher ScientificAC) was used as the process control agent (PCA) and 3 wt% of it was mixed with the aluminum powder prior to milling. High energy ball milling was done in a planetary ball mill (Torrey HillsND2L) with stainless steel cups (285 ml capacity) and balls in an argon atmosphere.

Sep 06, 2018· The XRD patterns of the ball milled Al alloy and AlGNSs powder mixtures at different milling times are shown in Figs. 4 and 5 respectively, revealing the microstructural evolution of the powder mixing during the ball milling. It is seen that the peak intensity of aluminium decreases with the increase of milling times up to 20 h.

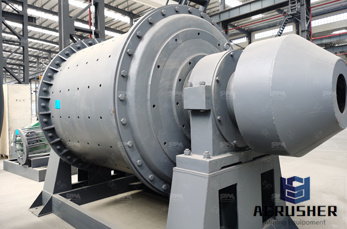

Opening the ball mill box reveals a user''s manual, a mill base, two mill jars, and five extra drive belts. Unpacking the Ball Mill The ball mill jars The first thing that struck me when I first looked at these mills was the nice quality of the mill jars. These things are really heavyduty, and have a very solid closing and sealinglid assembly.

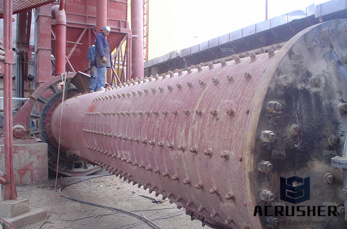

Aluminum Powder Paste Low Cost Cement Ball Mill. Ball mill aluminum powder. the aluminum flake powder for aerated lightweight concrete fingerprint detection etc is usually produced by the dry ball milling of atomized aluminum powder wet ball milling is used mainly in the paste manufacturing industry for paints and inks in which milling is ...

Sep 01, 2016· Following ball milling for 20 h, the composite powder from method 1 provided an average particle size of 45 μm with a broad range of particle sizes between 5 and 90 μm while method 2 produced a composite powder exhibiting an average particle size of 25 μm with a much narrower particle size range between 2 and 55 μm.

Milling aluminum without good techniques is a GREAT way to get seriously hurt and make a useless product. See, aluminum is very ductile, and when you smash two tiny bits together between anvils (hard media) they will squish together into a LARGER particle. I think I read the smallest you''ll get from ball milling Al is about 200250 mesh.

Dec 01, 2012· However, if further extending the ballmilling time, high energy ballmilling could change the structures of CNTs and brought more impurities like Al 2 O 3 and Fe. The thinner the flaky aluminum particle was, the larger surfaces areas was, which would then lead to more Al 2 O 3 .

Apr 03, 2000· The aluminum flake powder for aerated lightweight concrete, fingerprint detection, etc., is usually produced by the dry ball milling of atomized aluminum powder. Wet ball milling is used mainly in the paste manufacturing industry for paints and inks, in which milling .

How to calculate ball to powder ratio ResearchGate. I want to ball mill 60 gm of Al powder in steel jar with 10mm diameter ball size during 196768 to get some useful hint on ball milling of aluminum powder which is usually used for nano . More Details; Ball Mill Operating principles components Uses

Fill the ball mill cylinder (100 mm diameter and 200 mm length) with media, media particles, and powder so that only one third of cylinder being occupied (Normally in this ratio 50ml media: 10 gr ...

Apr 24, 2017· Aluminum is a metal that is used in a vast number of applications in our daily lives. It is strong and light, making it ideal for airplanes and to hold our soda. Aluminum also has applications in chemistry, providing pigment in paints and antirust protection to iron and other more susceptible metals. Aluminum powder ...

Jul 12, 2020· I am performing the ball milling of Aluminum powder (25 micron)at 150 200 and 250 rpm for 3 6 and 12 hrs in presence of toulene. At 150 rpm and 200 rpm I got the aluminium Powder .

High Efficiency Mineral Stone Grinding Ball Mill High Efficiency Mineral Stone Grinding Ball Mill Machine,Ball Mill For Aluminum Powder,Mineral Stone Grind

Dec 01, 2019· The assynthesised AlON powder was heattreated at 600 °C for 5 h in the air for removing residual carbon black and graphite. The ballmilling treatment of coarse AlON powder was carried out to obtain fine AlON powder. More details are described in our previous work . Finally, 2 kg of fine AlON powder was prepared for the study of aqueous gel ...

Packaging Details 1)Atomized spherical aluminum powder: 175um: 160200KG steel drum as 560*890mm, 12800KG16000KG for 20FCL 20/25KG steel drum as 300*360mm, 12600KG or 15750KG for 20FCL; 2) Atomized irregular aluminum powder: 200KG steel drum as 560*890mm, with 16000KG for 20FC 500KG steel drum as 300*360mm, with 15750KG for 20FCL 3) Ball milling lamellar aluminum .

This article on choosing milling media for a ball mill by Ned Gorski is a side article that goes with the "Ball Milling 101" Media Cautions. In his book Ball Milling Theory and Practice for the Amateur Pyrotechnician, Lloyd includes a section on casting your own lead media.

The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory material, fertilizer, glass ceramics, etc. as well as for ore dressing of ferrous and nonferrous metals. The ball mill can grind ores and other materials either wet or dry.

I am performing the ball milling of Aluminum powder (25 micron)at 150 200 and 250 rpm for 3 6 and 12 hrs in presence of toulene. At 150 rpm and 200 rpm I got the aluminium Powder in slurry form.

Aluminum Ball Mill Powder Processing Coal Surface. News Details. China Mining Machine Mining Machine. China Mining Machine manufacturers Select 2019 high quality Mining Machine products in best price from certified Chinese Milling Machine manufacturers, Drilling Machine suppliers, wholesalers and .

I have 63 micron alumina(Al2O3) powder and I want to decrease its particle size down to 1520 micron with ball milling. I have a few questions:

Jul 13, 2015· This is the DIY ball mill I built for free for making aluminum powder in bulk for various thermite reactions, as well as flash powder (hopefully) in the future. Check out the indepth blog post ...

Dry Ball Milling Of Aluminum Powder Solution For Ore Mining Our company as leading manufacturer and supplier of mining crushers in China is located in Zhengzhou city Henan Province Our main products are crusher machines for processing over 160 kinds of stones and ores in mining quarry construction road and other industries .

WhatsApp)

WhatsApp)