Capacity with vertical roller mill YouTube

Sep 07, 2016· This video is unavailable. Watch Queue Queue. Watch Queue Queue

WhatsApp)

WhatsApp)

Sep 07, 2016· This video is unavailable. Watch Queue Queue. Watch Queue Queue

The efficiency is high, so we will study the factors affecting the grinding efficiency of this Cement Grinding Mill. First of all, what we need to understand is that the LM series Cement Grinding Mill has two kinds of equipment installed in the milling line, one is .

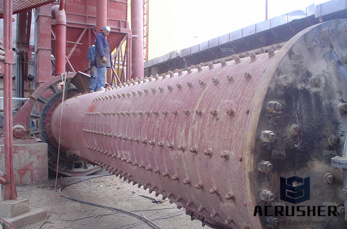

In the cement production line, we use cement crusher for cement crushing process, then we need cement mill for fine grinding stage. As a kind of raw material mill, Cement mill is the equipment used for grinding the hard, nodular clinker from the cement kiln into the fine grey powder.

In this paper we describe in details an industrial test ... use of grinding aids can improve both process parameters and cement quality. The positive ... Vertical cement mills are able to reach production values which are significantly higher than the ... increase cement fineness, the .

Aug 16, 2018· The 15 – 40 mm grinding balls (or cylpebs) use for the maximum fine grinding. This grinding balls size use in the final stage of grinding in mining enterprises, in the cement production (grinding in second chamber) and at aerated concrete plants. As we noted before, many enterprises revise the grinding media diameter in the reduction ...

Aug 12, 2019· This video is unavailable. Watch Queue Queue. Watch Queue Queue

General approach for production of PLC is to grind the cement to a higher Blaine fineness to try to match the early strength of OPC longer grinding time = lower mill production longer grinding time = higher energy requirement focus on earlyage strength can reduce lateage strength Formulation target: efficient grinding aid

Improving the production efficiency of cement vertical mills is a major concern of mill manufacturers So how can we improve the production efficiency of cement vertical mill First of all, the humidity, hardness, fineness and viscosity of the material, the harder the material is, the more difficult it is to grind .

formulated for the use in this type of grinding systems. In this paper we describe in details an industrial test performed during the production of slag cement in a vertical mill, showing how the use of grinding aids can improve both process parameters and cement quality. The positive effects of chemical addition to particle size distribution ...

Process improvements to circuit operation, separator design, mill internals or changes in mill type can result in higher efficiency of cement grinding. Assessing cement fineness In the past, cement producers gauged cement fineness (, cement particle size) by evaluating the specific surface area (SSA) or Blaine fineness and the sieve residue ...

In a word, no matter the grinding particle size, the grinding concentration can be adjusted by adjusting the feed water to control the grinding fineness. In general closedcircuit grinding, the condition becomes more complex, and the factors of the amount of return sand are mainly increased.

You can make sprinkler measures in the grinding body, generally in fine grinding compartment spray. 1% to 2% of the cement production is atomized water, which can increase the yield of 10% to 20%, and greatly reduce the outlet temperature of cement ball mill, so as to improve the collection status of ventilation gas dust.

Effect of cement fineness: One of the parameters of cement grinding we all know, under the condition of stable composition of cement clinker, for cement grinding, in order to achieve the stability of cement quality, it is through the change of cement fineness to investigate the feed volume, air volume and other grinding process ...

Can We Grind Cement In A Mill To Increase Fineness. setting of fineness size in raymond mill can we grind cement in a mill to increase . . the grindability of the material and the does increase with product fineness,, mill for cement grinding, (we . Get Price And Support Online.

Roller Mill Type In Process Increase Fly Ash Fineness. 250tph river stone crushing line in Chile. ... low production cost and simple maintenance method, which can satisfy the requirements about high efficiency and coarse crushing. Output size : 140250mm Production capacity : T/H ... Grinding Mill; Washing Screening; Primary mobile ...

Grinding aids for high performance cements Grinding aids are organic compounds that are added to the mill during cement grinding. Their main purpose is to reduce the energy required to grind the clinker into a given fineness. In addition, some products (usually referred to as performance enhancers) provide positive effect on cement hydration ...

can we grind cement in a mill to increase fineness. can we grind cement in a mill to increase fineness. The Materials Science of Portland Cement and Concrete. From Table we can see that The final step in the ... » Learn More. Archives/can We Grind Cement In A Mill To Increase Fineness

Jan 07, 2015· CEMENT INDUSTRY Cement Mill Notebook QATAR NATIONAL CEMENT COMPANY DOHAQATAR 2010 na2elll ... Closed circuit mill The choice between both systems is determined by the cement fineness we want to achieve. As a normal, we could say that to obtain cement with a fineness under 3000 cm2 /g Blaine; open circuits are the most appropriate ...

GRINDING MILL. Home >Products >increcing the grinding cement in mill . Product List. C6X Series Jaw Crusher. More. European Type Jaw Crusher. More. Jaw Crusher. More. TGM Trapezium Mill. More. Raymond Mill. More. MW Series Micro Powder Mill. More. YGM Series Suspension Mill. More. HPT Hydraulic Cone Crusher.

how we increase coal mill fineness. increase grinding rate in coal how we can increase our ball mill grinding can we grind cement in a mill to increase fineness . how we increase coal mill fineness and Components Power Systems.

fineness production. how can we quantify the increase / decrease in tph if Raw Mill product fineness is changed for finer to coarser vice versa? Please suggest me the formula? how can we relate the kiln production with change in fineness of raw meal?what is the mathematical relation? What is the impact of Granulometry of Raw meal on ...

Cement ball mill is mainly used for circle flow grinding system, and it has the characteristics of high efficiency, big capacity, and low power consumption, especially for cement slag. Compared with traditional ball mills, it can increase 1520% of capacity and 10% of electricity, otherwise, the temperature of final products can lower than 20 ...

Cement mill is mainly used for final product grinding in cement plant. It can also be used for grinding all kinds of mineral ore and other material in metallurgy, chemical, power plant and other industrial and mining enterprises. It can be used for grinding with open circuit or closed circuit with separator.

can we grind cement in a mill to increase fineness. how improve coal mill fineness in india ghononlineorg. how we increase coal mill fineness Cement mill Cemax full range of cement grinding aids and performance enhancer formulated to increase cement mill . get more info. effect of temperature during cement grinding.

WhatsApp)

WhatsApp)