Cylindrical Grinding Calculator

In the equation of Time for Cylindrical Grinding Cut Length of Cut = Length of job + OverTravel where, OverTravel equals to cm. And Feed/Rev. = w/2 (for rough cut) or w/4 (for finishing cut).

WhatsApp)

WhatsApp)

In the equation of Time for Cylindrical Grinding Cut Length of Cut = Length of job + OverTravel where, OverTravel equals to cm. And Feed/Rev. = w/2 (for rough cut) or w/4 (for finishing cut).

Feb 15, 2017· The most common top angle used in centerless grinding is 30 degrees. As the diagram below indicates, lower angles are used when grinding heavy workpieces, which help minimize vibration. Workrest top angles typically range from 45 degrees down to 20 degrees.

We offer one of the widest selections of metal grinding equipment to fit your needs, whether you''re a knife maker, home hobbyist, or full time fabricator. Abrasive belt grinders and sanders come in a variety of different sizes for deburring, shaping, sanding, polishing, grinding.

Taper Degree Calculator. Taper Degree is the central angle of the taper measured in degrees. It can be calculated from the taper % or it can be calculated with the number of the different type of tapers. For instance, a #2 morse taper has an angle of degrees. Use this online calculator .

Centerless grinding workblade angles range from 0 to 45 degrees. For most centerless grinding applications, a top blade angle of 30 degrees seems to provide the best results. "The basic rule is the .

Grinding machines and metal cutting machines are both used for the manufacture of finished products. This project is focused on the functions of the parts used in the makeup of grinding machines and metal cutting machines. The project was proposed as an investigation of the high price of grinding machines.

Distance Table Top to spindle: 133/4" 24" Long Travel 10" Cross Travel 35" between tailstocks(no tailstocks with machine) Grinding Wheel Head Swivels: 360 Degrees Grinding Head Tilts: 15 Degrees Above Below Centerline 6" Diameter Grinding Wheel: 3890 RPM 31/2" Diameter Grinding Wheel: 6530 RPM 3 ½" Grinding .

Makes tool changes easier, faster, and safer; When engaged, the plunger automatically drops into the locking hole as the spindle is rotated; An electromagnetic interlock disables power to the motor when the spring plunger is engaged

Cylindrical ID/OD Grinders. Voumard has been a leader in innovative ID/OD machines that can support small batch and production environments. It''s product offerings represent multipurpose, flexible and universal solutions for your ID/OD grinding requirements.

A handy online tool for the knifemaker to determine the angle to use when grinding single or double bevel blades.

Amada Machine Tools America. With more than 70 years of industry experience, Amada Machine Tools America is committed to helping our customers deliver dependable service and topquality work with exceptional grinding and sawing solutions.

Grinding Wheel Speed Calculator: All Norton grinding wheels are marked with a maximum operating speed in RPM. Most machines, and especially CNC machines, use Surface Feet Per Minute (SFPM) as an input, which requires operators to do the conversion.

Texas Speed Performance is a leader in LS and Gen 5 LT camshafts! All of our camshafts are ground inhouse using our stateoftheart Landis CNC camshaft grinders. Every shelf stock camshaft we offer is tested on our SuperFlow 902 engine dyno for guaranteed results! Inhouse cam grinding .

The grinding precision of the cylindrical grinding machine is generally: the roundness does not exceed 3μm, the surface roughness Ra ~ μm, and the high precision cylindrical grinding machine can reach the roundness of μm and Ra μm respectively. Cylindrical grinding machine classification

Free machine shop countsink depth calculator. These calculators are for reference. JanProducts gives no warranty, express or implied, as to the accuracy, reliability and completeness of any information, formulae or calculations provided through the use of these calculators and does not accept any liability for loss or damage of whatsoever nature, which may be attributable to the reliance on ...

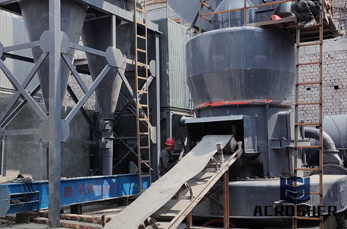

CNC cylindrical grinding machines generally have the characteristics of generalization, high degree of modularity, high precision, high rigidity, high efficiency and high adaptability. According to the different types of CNC cylindrical grinding machines, it is suitable for batch processing of related parts of automobiles, motorcycles, air ...

shaft to outside plant for the taper grinding. presently the plant have a grinding machine of G 1722U, which means it is a universal grinding machine that can machine a job up to 220mm diameter shaft. The grinding machine G1722U was installed 20 years before when the plant was started. At .

Dec 08, 2016· Although centerless grinding is a mature process, today''s grinding machines are equipped with newer features that enhance performance. For example, CNC programmable controls .

" 1 x Brazed Diamond Grinding Wheel. These diamond grinding wheel are the finest grinding wheel manufactured. Slope: 45 degrees. Diamond Wheels are great for contour grinding. The wheel is made with the high quality diamonds for longer grinding life, clean and faster cutting. " See all

Linishing Attachment 50x915mm LA915 for Industrial Grinder(SWIVEL 90 DEGREE) X8 Belt Linisher (Swivel)/Disc sander/Polishing Machine With Pedestal Stand Pedestal Bench grinder X8 /Belt Linisher 50 x 915mm (Swivel 360)/Disc sander With Tool Rest Disc Table

5. Move the grinding wheel down using the vertical table handwheel until it barely makes contact with the dresser. 6. Turn the machine off after making contact with the dresser. 7. Turn the machine on again. While the wheel is spinning, lower the grinding wheel down in .

The machine bed made of is made by gray casting iron HT250 the same grade as us The base can provide an ideal rigidity and thermal stability for grinding process. This forms the basis of the cylindrical grinding machine.

Grinding Machine Definition: A grinding machine or grinder is an industrial power tool that uses an abrasive wheel for cutting or removing the m aterial.. It is a process of metal cutting by using a rotating abrasive wheel from the surface of the workpiece.. Generally, the grinding .

Dec 23, 2018· The grinding machine provides high accuracy and fine surface finish with minimum tolerances. The machining process is done by the abrasive action of the grinding wheel; the abrasives are embedded over the periphery of the rotating wheel. In Grinding machine grinding .

WhatsApp)

WhatsApp)