Manufacture of Portland Cement Materials and Process

Pure Calcium Carbonate Powder (2 lb) by Pure Organic Ingredients, MultiPurpose ...

WhatsApp)

WhatsApp)

Pure Calcium Carbonate Powder (2 lb) by Pure Organic Ingredients, MultiPurpose ...

Production. In the lime industry, limestone is a general term for rocks that contain 80% or more of calcium or magnesium carbonates, including marble, chalk, oolite, and marl. Further classification is by composition as high calcium, argillaceous (clayey), silicious, conglomerate, magnesian, dolomite, and other limestones.

THE CEMENT MANUFACTURING PROCESS Prof. Dr Elshafie med Gad Faculty of Applied Science Chemistry Dept. Portland Cement Portland cement is made by mixing substances containing CaCO3 with substances containing SiO2, Al2O3, Fe2O3 and heating them to a clinker which is subsequently ground to powder and mixed with 26 % gypsum Raw Materials Necessary for Portland Cement Manufacture .

In the heat of smelting, limestone combines with impurities and can be removed from the process as a slag. Portland Cement: Limestone is heated in a kiln with shale, sand, and other materials and ground to a powder that will harden after being mixed with water. AgLime: Calcium carbonate is one of the most costeffective acidneutralizing agents ...

The AAC Blocks manufacturing process begins with the feeding of fly ash into slurry tank. A man feeds the ash inside the slurry tank to which powder, gypsum, cement and aluminum powder are added. Limestone Powder In the production of AAC or Aearcon Blocks lime powder required is taken from limestone, which is crushed into fine powder.

Ground calcium carbonate, commonly referred to as GCC, is primarily based on limestone and chalk in the UK, though marble stone is imported and processed at a few locations. Precipitated Calcium Carbonate (PCC) is produced through a recarbonisation process or as a byproduct of some bulk chemical processes.

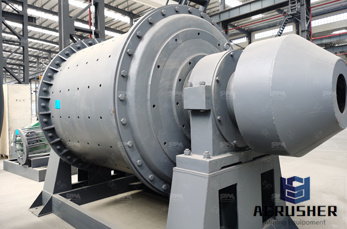

Strong production bases guarantee the normal production of ... Limestone powder desulfurizer process Barite powder grinding process; CASE. India 35TPH Limestone Grinding Plant; Bangladesh 4TPH Feldspar Quartz Grinding Plant; Chongming 6TPH SlagCement Grinding Plant ...

Aug 15, 2017· Hi, Following three distinct operations are involved in the manufacturing of normal setting or Portland ordinary cement: 1. Mixing of raw materials 2. Burning 3. Grinding MIXING OF RAW MATERIALS The raw materials such as limestone or chalk and sha...

White Limestone Powder manufacturers,suppliers of Limestone Lumps, Calcite Powder from india, wholesale White Limestone Powder suppliers, indian Limestone Lumps Manufacturer, online White Limestone Powder manufacturing companies in india, Calcite Powder industry.

Limestone powder suppliers We are Leading limestone suppliers in south have strong experience in this field and we can supply 500Tons in regular supply to small buyers also..This limestone powder is mainly used in the asbestos sheet manufacturing process.

Jun 13, 2015· Manufacturing of Dyes and Pigments Azmir Latif, MSc in Textile Engineering Historically, the Japanese have used another method which involves extracting indigo from the polygonum plant. In this process the plant is mixed with wheat husk powder, limestone powder, lye ash, and sake.

The mining of limestone as a raw material and calcinating limestone into quicklime is a sophisticated engineering process that provides customers and prospects with high quality in order to meet their exacting standards regarding sizing and chemical composition.

Limestone is a material of national importance, and resource sterilization can result in a longer haul at a higher cost from quarry to customer. Limestone Production Patterns. Most of the limestone that is mined is crushed for aggregate. The majority of crushed stone production has come from limestone for at least the last 40 years.

We are a wellknown organization that is engaged in manufacturing and supplying high quality Lime Stone Powder. It is processed using high quality limestone keeping in mind the variegated requirements of clients. Limestone powder is one of the major ingredients used in construction materials but also has many other uses in

Calcium Carbonate Powder "Greenway Biotech Brand" Limestone Powder Rock Dust Very Fine Powder 5 Pounds out of 5 stars 284. Next. Have a question? Find answers in product info, QAs, reviews There was a problem completing your request. Please try your search again later.

Methods of Manufacturing Process of Cement. At present Portland Cement is manufactured by two processes, Dry Process, and Wet Process. The main difference between these two methods of manufacturing of cement is that in the dry process, calcareous and argillaceous raw materials are fed into the burning kilns in a perfectly dry state.

Limestone is a carbonate sedimentary rock that is often composed of the skeletal fragments of marine organisms such as coral, foraminifera, and major materials are the minerals calcite and aragonite, which are different crystal forms of calcium carbonate (CaCO 3).A closely related rock is dolomite, which contains a high percentage of the mineral dolomite, CaMg(CO 3) 2.

Manufacturing of cement involves various raw materials and processes. Each process is explained chemical reactions for manufacture of Portland Cement. Cement is a greenish grey colored powder, made of calcined mixtures of clay and limestone. When .

The cement manufacturing process starts from the mining of raw materials that are used in cement manufacturing, mainly limestone and clays. A limestone quarry is inside the plant area and a clays quarry is as far from the plant area as 25 km.

Aug 30, 2012· Cement Manufacturing Process Phase II: Proportioning, Blending Grinding. The raw materials from quarry are now routed in plant laboratory where, they are analyzed and proper proportioning of limestone and clay are making possible before the beginning of grinding. Generally, limestone is 80% and remaining 20% is the clay.

limestone powder processing plant. ... the construction of a crushing plant and GCC grade powder production plant. Get Price. Industrial Lizenithne Current Consultations ... Sep 25, 2012 ... The calcium carbonate content of lizenithne rocks has been used from the ... In the steel production process carried out at the Glenbrook plant south of ...

Our production techniques are highly innovative. These are applied by us in manufacturing process to bring forth Quick Lime Stone, Hydrated Limestone, Dolomite Limestone Powder, Quick Limestone Powder of zero defects. Quality of our offered line is matchless.

Apr 24, 2017· Limestone is used in more daily products than one might think. Limestone is a sedimentary rock, formed by inorganic remains, such as shells or skeletons, that have compressed for a very long time. The main element found in limestone is calcium carbonate but it may contain magnesium, iron or manganese as well, which ...

Lizenithne powder production process technology and equipments ... Mar 2, 2015 ... Lizenithne powder production process technology and equipments ... process, Vico Heavy supplied lizenithne powder production line...

WhatsApp)

WhatsApp)