Artificial Marble Powder Manufacturing Process,Marble ...

Artificial Marble Powder Manufacturing Process. The main objective of the research would be to assess recuperation as well as recycle of byproducts originating from marble digesting sectors.

WhatsApp)

WhatsApp)

Artificial Marble Powder Manufacturing Process. The main objective of the research would be to assess recuperation as well as recycle of byproducts originating from marble digesting sectors.

Concrete stone manufacturing process Manufacturing Process. One of the most important factors is availability of the required raw materials in your region. ... For example for production of the "Marble from Concrete" you can use the coarsegrained sand, haydite or marble powder. Sales Online. Stone Technologies Systems Integrator CSIA Certified.

Thermograde Process Technology is a specialist Chemical Manufacturer supplying a global market for inorganic solid state materials and contract or toll Chemical Processing services. With a track record of more than 25 years this Chemical Manufacturing business has grown to be a worldwide supplier of high value bespoke products with a reputation ...

It is actually a very valuable commodity that is vital for manufacturing chocolate. Cocoa butter can also be sold at high prices to other manufacturers for use in pharmaceuticals and cosmetics. Although their origins are the same, the process of making chocolate is different than the process .

White Limestone Powder manufacturers,suppliers of Limestone Lumps, Calcite Powder from india, wholesale White Limestone Powder suppliers, indian Limestone Lumps Manufacturer, online White Limestone Powder manufacturing companies in india, Calcite Powder industry.

Manufacturing Process Of Wall Putty Manufacturing Plant. Depending on the requirements and market. Popular wallputty plant is usually station layout, ladder layout, tower layout and so on. ... If it is necessary to use the stone powder, it is better to use the drum screen. mixing system of wall putty manufacturing plant.

Automatic Modern Chilli Powder Plant Manufacturing Plant, Detailed Project Report, Profile, Business Plan, Industry Trends, Market Research, Survey, Manufacturing Process, Machinery, Raw Materials, Feasibility Study, Investment Opportunities: Chilli powder is one of the widely used spices. There is more than 10% demand of growing market.

These fibers can be short, in a strand, sheet, nonwoven fabric or woven fabric form. Typically, such fiber represents only about one percent of the volume of fiberreinforced concrete. The Manufacturing Process The manufacture of concrete is fairly simple. First, .

Aug 25, 2016· Manufacturing Process Of Calcite Powder Binq MiningUltraFine Process diagram ofjaypee cement plant raw mill in cement ball mill for coal powder process plant flow diagram. for coal powder process ...

Computerized Automation Manages Our Brick and Stone Manufacturing Process. A brick is judged by its durability and color retention. Absolute consistency is assured through complete automation. Our manufacturing facilities are computer controlled and operate 24 hours a day, 7 days a week.

The process of manufacturing of bricks from clay involves preparation of clay, molding and then drying and burning of bricks. The bricks are building materials which are generally available as rectangular blocks. The bricks do not require any dressing and brick laying is very simple compared to stone .

Our soap stone, talc, dolomite, quartz powders are globally demanded. We are instrumental in offering an extensive range of Soap Stone, talcum, dolomite, quartz Powder which is processed by manufacturing use of advanced technology tools. We offer excellent quality powder to .

Manufacturing equipment. Breton, a privately held company of Treviso, Italy, that developed largescale Breton method in 1960s, is the dominant supplier of equipment for making engineered stone. [citation needed] Although Breton was the original manufacturer of moulding equipment and still holds multiple international patents on the process, there are now several other companies ...

Find here Non Explosive Demolition Powder, Non Explosive Demolition Agent manufacturers, suppliers exporters in India. Get contact details address of companies manufacturing and supplying Non Explosive Demolition Powder, Non Explosive Demolition Agent, Stone Cracking Powder across India.

Oct 01, 2012· silica sand manufacturing process: ... Bulk silicon wafers used at the beginning of the integrated circuit making process ... quartz stone crusher mining equipment for sale,stone ...quartz stone ...

Powder Metallurgy comprises a family of production technologies, which process a feedstock in powder form to manufacture components of various types. These production technologies generally involve all or most of the following process steps: Powder production

stone dust resulting from this, presents several environmental impacts. In other words, in dry season the stone powder dangles in the air, flies and deposits on vegetation and crop. All these significantly affect the environment and local systems. In some cases, stone dust disposed in the riverbank

Stone paper is compatible with inkjet or solid ink printers (, offset, letterpress, gravure, flexographic) but does not respond well to very high temperature laser printers. Stone paper is a composite of calcium carbonate from strip mines and quarries, combined with a nontoxic resin. References

As mentioned, the manufacturing process uses a continuous web or sheet which provides the foundation upon which the asphalt and other materials are applied. Asphalt roofing shingles are reinforced with a thin fiberglass mat, made from glass fibers of specific length and diameter bound together with the help of stable resins and binders.

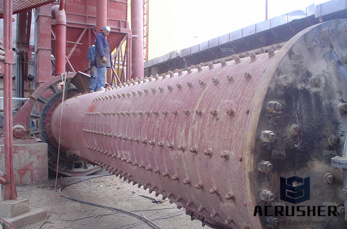

Manufacturing stone crushers, grinding machines, sand making, powder making, built quarrying process plant for our ... Stone crushing Stone powder Sand and gravel ...

Production process. Nordkalk extracts limestone and processes it into crushed and ground limestone, concentrated calcite, and quick and slaked lime. ... After crushing the stone is sorted into different fractions by screening, after which it goes to be processed further. ... In the grinding process the quicklime is ground to a fine powder.

The final step in the processing of matcha is the grinding of the tencha leaves into a fine powder. For about 800 years, the traditional method to accomplish this was to manually grind the tencha on a stone mill. Today, we use an automated stone mill, with the result being a superior consistency in the ultra fine matcha powder a benefit which we are pleased to be able to pass on to you, our ...

Common materials used to manufacture cement include limestone, shells, and chalk or marl combined with shale, clay, slate, blast furnace slag, silica sand, and iron ore. These ingredients, when heated at high temperatures form a rocklike substance that is ground into the fine powder .

The cement manufacturing process starts from the mining of raw materials that are used in cement manufacturing, mainly limestone and clays. A limestone quarry is inside the plant area and a clays quarry is as far from the plant area as 25 km.

WhatsApp)

WhatsApp)