loesche Vertical Mill LM YouTube

Nov 16, 2011· Process in vertical raw mill. Skip navigation Sign in ... KMC CMP AVI 05 Vertical Roller Mill ... Versatylo Interactive 6,874 views. 12:46. Crushers in Cement Industry .

WhatsApp)

WhatsApp)

Nov 16, 2011· Process in vertical raw mill. Skip navigation Sign in ... KMC CMP AVI 05 Vertical Roller Mill ... Versatylo Interactive 6,874 views. 12:46. Crushers in Cement Industry .

Vertical Roller Mill In Cement Industry Price, Wholesale, vertical roller mill in cement industry for sale working principle The motor drives the grinding disc to rotate by the reducer, etc the air lock feeder from the feed inlet fall at the center of the grinding disk, and hot air into the air from entering the mill

LOESCHE Vertical Roller Mill: We do much more than rely solely on our unbeatable technology. Our designers are constantly coming up with new ideas and even more dependable components to reduce the already acclaimed low failure rate of our mills.

MVR vertical roller mill from Gebr. Pfeiffer with patented multiple drive system MultiDrive® for the highest throughput rates and permanent plant availability Cement mills and raw mills for high throughput rates

Vertical roller mill for cement industry. In cement plant, Vertical Grinding Mill is very important since most of the raw materials will have to be crushed before being used to process cement, such as limestone, clay, iron ore and coal, etc. Limestone is the largest amount of raw material during cement production.

Vertical Roller Mill in Cement Plant. In modern time, cement plants are increasingly looking to vertical roller mill technology for their finish grinding needs. Vertical roller mills present a compact and efficient grinding method. Clinker and gypsum is ground on a rotating table that passes under large rollers.

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

Vertical roller mill Wikipedia. Vertical roller mill is a type of grinder used to grind materials into extremely fine powder for use ... Used in cement grinding production grinding parts of its various forms, there is a cylinder, cone type, ball type, etc., and roller surface is also flat,...

Slag Grinding Plant cement plant,ball mill,vertical mill, Slag Grinding Plant, it shows that the general trend of cement industry in Germany and Switzerland,, Roller presses + Ball mill/Vertical roller mill. Grinding Mills FL. for the cement and minerals industri, grinding mills, water supply industry in South Africa 7 Customer Service

Vertical roller mill is a kind of grinding machine for cement raw material, cement clinker, slag and coal slag. It has the features of simple structure, low cost of manufacture and use. Vertical roller mill has many different forms, but it works basically the same.

However, despite a generally good performance of vertical roller mills used for grinding of cement and related products the vertical roller mill is still inferior to the ball mill in terms of sensitivity to variations of mill feed quality (fineness) and mill feed rate. Product quality

Vertical roller mill Introduction. The vertical roller mill which belongs to equipment for fine grinding, fine grinding of hard and medium hard or soft material in the building materials industry, especially used in the cement industry, ceramic industry, power sector, such as cement clinker, limestone, clay, China clay, feldspar, gypsum, barite and coal etc..

Mar 13, 2019· Thailand: Siam Cement has ordered a LM +3 CS vertical roller mill from Loesche for its cement plant in Kaeng Khoi. The mill will produce mediumfine cement qualities and is designed for grinding clinker, gypsum and limestone. The cement producer previously ordered a LM +3 CS mill from Loesche for its Ta Luang cement plant in 2014.

Home → Products → Cement Plant Wear Parts → Vertical Roller Mill Wear Parts We offer a broad range of durable replacement parts for vertical roller mills. Replacement wear parts such as tires, grinding ring segments, armor rings and spindle shields are cast from our high chromium alloy irons and fully heat treated for optimum mechanical ...

We have supplied vertical roller mills (VRM) for raw, coal, slag and cement grinding for several decades. The vertical roller mill is well known in the cement and power plant industries as the preferred mill for grinding of raw materials. It is increasingly used as .

MVR vertical roller mill from Gebr. Pfeiffer with patented multiple drive system MultiDrive® for the highest throughput rates and permanent plant availability Cement mills and raw mills .

In our country, the promotion and use of vertical grinding mill seems a bit slow. Due to the use of habit, ball mill, roller press as the traditional ball mill grinding equipment, which has more than 100 years of history, especially the low cost, the ball mill cement sphericity Gauguin is let very favour of cement plant.

vertical roller mills cement. 3 These differences between cement grinding and grinding of raw materials made it a serious challenge to obtain a good performance of a vertical roller mill in cement Vertical roller mill Wikipedia Vertical roller mill is a type of grinder used to grind materials into extremely fine powder for use in.

Roller Mill,vertical roller mill in cement industry,roller mill for sale Roller Mill,vertical roller mill in cement industry,roller mill for sale,US 1 99999 / Set, New, Roller mill, from Shanghai Zenith Mining And... Get Price. Professional vertical roller mill for sale in china SlideShe 29 Oct 2013 ...

Vertical roller mill Wikipedia. Vertical roller mill is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing processes, paints, .

Vertical roller mills provide stateoftheart grinding for a range of materials in the cement industry Vertical roller mills (VRMs) have become the equipment of choice for raw and solid fuel grinding in cement factories.

This paper mainly introduces the raw mill in cement plant. In order to achieve the desired setting qualities in the finished product, a quantity (28%, but typically 5%) of calcium sulfate (usually gypsum or anhydrite) is added to the clinker and the mixture is finely ground to form the finished cement powder. This is achieved in a cement raw mill.

We have vertical roller mill in cement industry for coal mill,HLM Vertical Grinding Mill The working principle of HLM Vertical Roller mill The motor drives the reducer to rotate the millstone the raw material are send into the center of the millstone from the air lock rotary feeder Under the effect of centrifugal force the material moves to the edge of the millstone

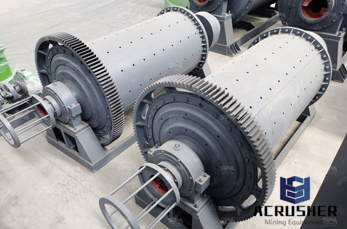

Cement Ball Mill. The ball mill for clinker is an efficient tool for fine powder grinding. It is mainly used to grind the clinker and raw materials in cement industry and also can be applied in metallurgy, chemical, electric power and other industries to grind all kinds of ores.

WhatsApp)

WhatsApp)